Infineon to Start 300 mm GaN Wafer Production as TSMC Exits Market

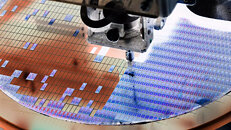

Infineon has announced that its gallium nitride (GaN) power semiconductor production is on schedule, confirming that its 300 mm wafer fab will deliver customer samples in Q4 2025. The German semiconductor manufacturer becomes the first company to successfully integrate 300 mm GaN wafer technology into its existing high-volume production infrastructure, achieving a 2.3x higher chip yield per wafer compared to conventional 200 mm processes. Infineon plans to capitalize on the projected annual market growth of 36%, with GaN power applications expected to reach $2.5 billion by 2030, according to an analysis by the Yole Group. The timing proves particularly strategic, as TSMC has announced plans to shut down its GaN production lines and dismantle facilities within two years, creating a significant market vacuum.

The new announcement addresses a fundamental industry challenge: scaling GaN production while maintaining cost competitiveness with silicon alternatives. Infineon's integrated device manufacturer (IDM) model provides complete process control from wafer fabrication through final product delivery, enabling what the company projects will be cost parity between comparable silicon and GaN devices. Johannes Schoiswohl, Head of GaN Business Line, emphasized that the scaled 300 mm manufacturing leverages Infineon's existing infrastructure investments while supporting rapid capacity expansion for emerging applications, including AI system power supplies, automotive charging systems, and industrial motor control. TSMC's strategic retreat from GaN manufacturing indicates that the company's focus remains on high-margin logic processors, leaving specialized power semiconductor companies like Infineon to dominate the expanding GaN market. In this market, GaN's superior power density, switching speeds, and thermal performance deliver measurable system-level advantages over traditional silicon-based solutions.

The new announcement addresses a fundamental industry challenge: scaling GaN production while maintaining cost competitiveness with silicon alternatives. Infineon's integrated device manufacturer (IDM) model provides complete process control from wafer fabrication through final product delivery, enabling what the company projects will be cost parity between comparable silicon and GaN devices. Johannes Schoiswohl, Head of GaN Business Line, emphasized that the scaled 300 mm manufacturing leverages Infineon's existing infrastructure investments while supporting rapid capacity expansion for emerging applications, including AI system power supplies, automotive charging systems, and industrial motor control. TSMC's strategic retreat from GaN manufacturing indicates that the company's focus remains on high-margin logic processors, leaving specialized power semiconductor companies like Infineon to dominate the expanding GaN market. In this market, GaN's superior power density, switching speeds, and thermal performance deliver measurable system-level advantages over traditional silicon-based solutions.